Contact Fangrongcontact

DongGuang FangRong Seiki Kogyo Co., Ltd.

Address: Dongguan City, Guangdong Province town of Lang Sha step Second Industrial Zone No. 163 sand path

Phone:139-2291 2617 (Mr Lai)

Plane:86-769-8320 2640

fax:0769-8312 6559

mailbox:dgfangrong@126.com

URL:www.xmwangda.cn

V-groove thread forming machine ------------------------------------------- ------------------------------------ for metal pipe

Name: V-groove thread forming machine

Usage: Suitable for interior air conditioning evaporator fin tube, dry steam tube, threaded inner fin tube forming.

Mechanical Layout: Horizontal

Weight: 15000kg

V-disc diameter: Ф2000mm

Process specifications: Ф5-9.52mm

Maximum speed: 100M

Total power: 41KW

Spin casting speed: 0-35000rpm

Forming speed: 30-90m / min

First, the thread forming Product Overview:

Uses: This equipment is suitable for molding inner fin tube air conditioning evaporator V-thread

Mechanical Layout: Horizontal

Second, the thread forming operation mode:

Using disk pull mode, when drawing the brass plate on the market may be the number of turns, the disk side has a pinch roller, thus avoiding the V-groove slippage, while avoiding the market due to the V-groove in contact with the brass is too short for a long time V-groove drawing excessive wear and ovality much of a problem, when the drawing device can monitor the quality of the outer surface of the brass.

Internal thread machine equipment capacity:

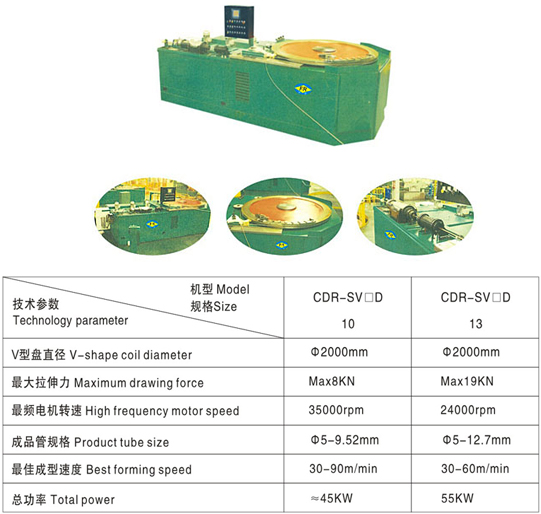

A. V-type disc diameter CDR-SV port D 10 Ф2000mmCDR-SV port D 13 Ф2000mm

B. The maximum tensile force CDR-SV port D 10 Ma * 8KNCDR-SV port D 13 Ma * 19KN

C. The most frequent motor speed CDR-SV port D 10 35000rpmCDR-SV port D 13 24000rpm

D. Finished pipe specifications CDR-SV port D 10 Ф5-9.52mmCDR-SV port D 13 Ф5-12.7mm

E. Optimum forming speed CDR-SV port D 10 30-90m / minCDR-SV port D 13 30-60m / min

F. Total power CDR-SV port D 10 ~ 41kwCDR-SV port D 13 ~ 55kw

DongGuang FangRong Seiki Kogyo Co., Ltd. all rights reserved Straightening machine, steel straightening machine, pipe straightening machine

DongGuang FangRong Seiki Kogyo Co., Ltd. all rights reserved Straightening machine, steel straightening machine, pipe straightening machine